econ industries

Booth number: 8750

econindustries.com

About us

econ industries offers solutions for the treatment of industrial hazardous wastes and contaminated soil, based on 20+ years of experience and more than 30 industrial waste recycling plants. econ’s aim is to avoid the elimination of waste through incineration and landfilling but to achieve a resource-conserving material recycling instead. In our plants we primarily use VacuDry® technology, in which the harmful substances (e.g. hydrocarbons, mercury) are separated under heat and vacuum in a fully encapsulated system. Particularly when it comes to energy efficiency, low carbon emissions and resource recovery rates, this method is far superior to other thermal distillation techniques and is accepted as state of the art by approval authorities worldwide. Tailor-made research, development, consulting, engineering, delivery, and commissioning are our core competencies.

Address

Schiffbauerweg 1

82319 Starnberg

Germany

E-mail: sales@econindustries.com

Phone: +49 8151 4463770

Internet: www.econindustries.com

Contact person:

Products & Services

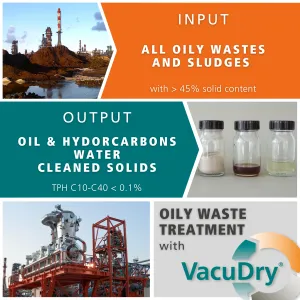

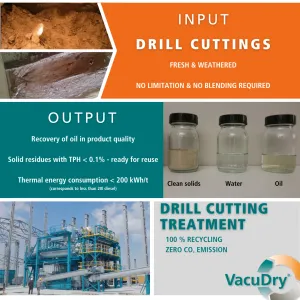

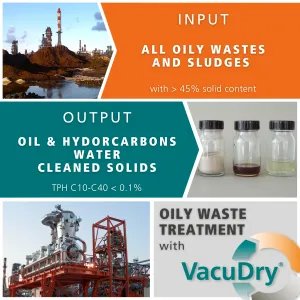

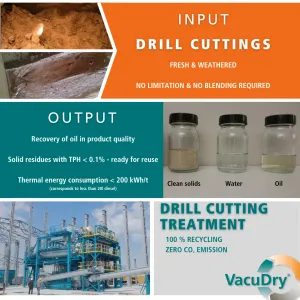

econ industries profession is designing, manufacturing, and commissioning of highly efficient equipment for the recovery of resources from industrial hazardous wastes such as contaminated soils, oil sludges, NORM waste and metal sludges among others. The VacuDry® plants are built in skid mounted units, which can treat ~10 – 250 tons per day. They can be used mobile on site or in stationary operation.

For the conversion of elemental mercury, econ industries offers the only mobile solution worldwide. The MMCU - Mobile Mercury Conversion Units are available in two plant sizes. The MMCU 150 and MMCU 1 500 enables the customer onsite to convert 200kg - 1.5 ton of elemental mercury to mercury sulfide.

VacuDry®

VacuDry® is our vacuum thermal distillation technology The VacuDry® plants are built in skid mounted units, which can treat ~10 – 250 tons per day. They can be used mobile on site or in stationary operation.

Typical applications of our VacuDry® technology are the treatment of contaminated soils and sludges (hydrocarbons, PCB, mercury, PFAS/PFOS, solvents, etc.), mercury wastes, drill cuttings, grinding swarf and sludges from metal processing, refinery wastes and NORM waste among other.

MMCU - Mobile Mercury Conversion Unit

For the conversion of elemental mercury, econ industries offers the only mobile solution worldwide. The MMCU - Mobile Mercury Conversion Units are available in two plant sizes. The MMCU 150 and MMCU 1 500 enables the customer onsite to convert 200kg - 1.5 ton of elemental mercury to mercury sulfide.The econ team has already stabilized 500 tons of elemental mercury in Europe and offers its equipment worldwide. Now it is official and Australia gets its first own mercury stabilization.

---watermark-small-thumb.webp)

---watermark-small-thumb.webp)