GEA Westfalia Separator Group GmbH

Booth number: 8753

www.gea.com/en/united-arab-emirates

About us

GEA is one of the world’s largest systems suppliers for the food, beverage and pharmaceutical sectors. Our portfolio includes machinery and plants as well as advanced process technology, components and comprehensive services. Used across diverse industries, they enhance the sustainability and efficiency of production processes globally. The company supports customers across the entire value chain, from upstream oil & gas production to midstream transport and downstream refining. GEA's portfolio includes highly efficient separation, heat exchange, and refrigeration technologies designed to increase process reliability, reduce energy consumption, and meet stringent environmental regulations. Backed by decades of engineering expertise and global service capabilities, GEA is a trusted partner for optimizing processes and securing long-term profitability in the oil & gas industry.

Address

Werner-Habig-Str. 1

59302 Oelde

Germany

E-mail: info@gea.com

Phone: +49 2522 77-0

Internet: www.gea.com

Jebel Ali Free Zone, Gate 4, LB 15

Office 601

P.O. Box 262952 Dubai

United Arab Emirates

E-mail: geamiddleeast.info@gea.com

Phone: +971 4 887-5650

Internet: www.gea.com/en/united-arab-emirates

Contact person:

Uwe Schmiemann

Senior Director Business Line Oil & Gas and Energy

E-mail: Uwe.Schmiemann@gea.com

Phone: +49 2522 77-1134

Adel Alotaibi

Senior Director Representative Separation and Flow Technologies Middle East & Egypt

E-mail: Adel.Alotaibi@gea.com

Phone: +971 4 887-5650

Products & Services

Since 1893, GEA has been building centrifuges which combine high separating efficiencies, clarifying efficiencies and throughput capacities with maximum savings in terms of energy, water and disposal costs.

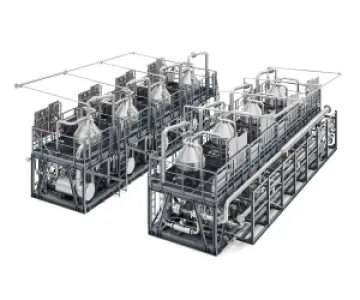

Centrifugal separator

GEA separators are designed for liquid-based applications. Using centrifugal force, they are used for separating suspensions consisting of two or more phases of different densities, i.e. they can be used for liquid-liquid separation, for liquid-liquid-solid separation or for liquid-solid separation. They are equally as effective at separating liquid mixtures at the same time as removing solids.

Decanter centrifuge

The decanter’s hour has come as soon as the solids content in the suspension to be processed is particularly high. These machines provide the benefits of high clarifying efficiency and maximum dewatering as well as the separation of liquids with the simultaneous removal of solids. The main requirements in this respect include a high bowl speed, a powerful drive for the scroll and a scroll speed which automatically adapts to the solids loading in the feed.

-thumb.webp)