M+F Technologies GmbH

Booth number: 13390

www.m-f.tech

About us

M+F Technologies GmbH is part of the J.H.K. Group and specialises in custody transfer flow measurement of liquid and gaseous energy sources. Our primary focus is on loading systems for tank trucks, rail trains, and ships, as well as fuel supply systems incl. SAF blending for airports.

In addition to the delivery and blending process for e-fuels such as GTL and GTX, systems for “green” methanol bunkering and HVO loading systems have been successfully implemented.

Address

Helbingtwiete 5

22047 Hamburg

Germany

E-mail: info@m-f.tech

Phone: +49 40 725500

Internet: www.m-f.tech

Contact person:

Products & Services

The high performance MFX_4 flow computer family complies the highest standards for flexible and reliable custody transfer measurement. Furthermore, the COTAS ® Terminal Management System forms the basis for recording all incoming and outgoing transactions, as well as for inventory management and participation in custody authority driven procedures. Last but not least, COTAS provides the platform for calculating energy taxes and reporting for emission declarations.

Flexibility: a wide-ranging system family with modules for use in control rooms and external use in explosive environments, even under extreme weather conditions

Scalability: use in various applications, ranging from systems with single loading stations to large, complex transfer systems

Security: rigorously secure parameter access through structured system admission as part of a multi-level security approach with the archiving of all changes

MFX_4 Pro

The MFX_4 Pro widens our range of HMI devices based on our proven MFX_4 Terminal. It offers an impressive user friendly interface with a high contrast 10,4” colour display enabling the reading from larger distances. Just like the MFX_4 Terminal, it is a multi-language Human Machine Interface (HMI) to interact with MFX_4 Controller, other suitable terminals or with host computer systems via a wide range of communication protocols.

MFX_4 Controller

The MFX_4 Controller is the centralised control unit of the MFX_4 system. It is available in two housing variants as an explosion-proof (Ex) as well as an unprotected device, whereby the functionality of the electronics is identical. Depending on the model, it can be used both in the control room and under extreme weather conditions in explosive external areas.

Terminal Automation System COTAS

The software solution for greater flexibility

The terminal automation system COTAS is the complete solution for product transfer management and the controlling of all loading processes in the tank farm. The PC-based software coordinates the business processes from storage and multi-client stock balancing to dispensing. COTAS is linked to all instrumentation in the field and controls the loading processes.

Thanks to its diverse and open interfaces COTAS can integrate various measurement devices without difficulty and can itself be easily incorporated into higher-level ERP systems such as SAP. Its highly flexible configuration means that COTAS can also be deployed rapidly in both small and large tank farms without any programming work.

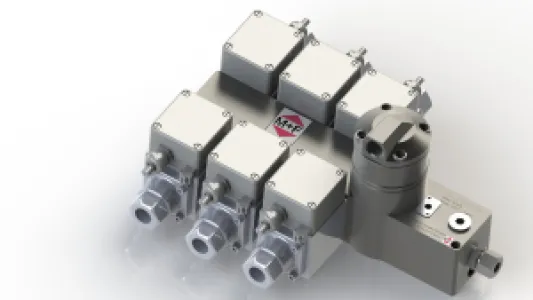

M+F Additivation Systems

Due to the growing demands for flexibility in the field of additives, we have successively expanded our product portfolio in recent years. Today we can fall back on CBU variants which, taken together, meet all the requirements of modern dosing systems.

Solo or built into a protective housing and optionally heated, they not only offer protection against tampering, but also allow installation and operation under the harshest of weather conditions.